Importance of Regular Maintenance and Inspection

The Importance of Regular Maintenance and Inspection in Gas Furnace Repair Techniques

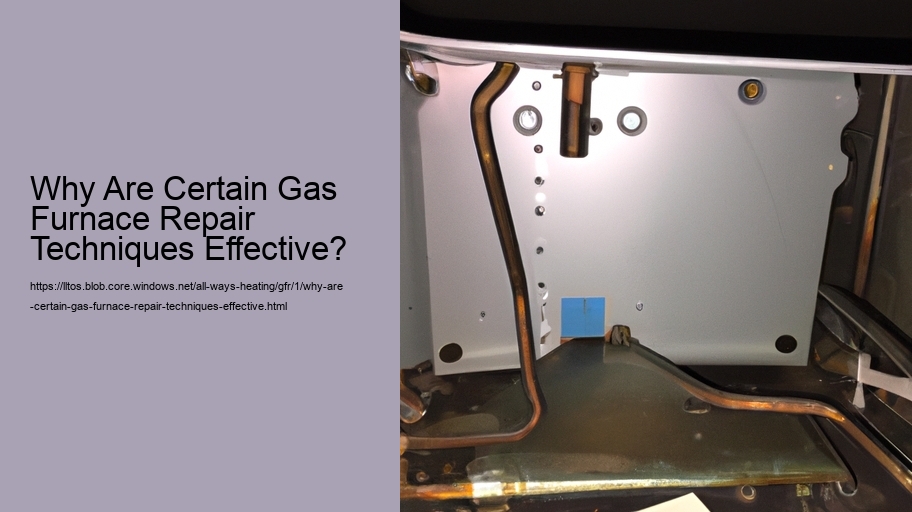

When it comes to maintaining a comfortable and safe living environment, the efficiency and reliability of a gas furnace cannot be overlooked. Get in touch with All-Ways Heating & A/C for gas furnace repair services you can count on in Everett WA. The key to ensuring that your gas furnace operates effectively lies in regular maintenance and inspection. This practice not only extends the lifespan of the heating system but also plays a crucial role in determining why certain repair techniques are effective.

Regular maintenance involves routine checks and minor adjustments to ensure that every component of the furnace is working as intended. During these checks, technicians can spot early signs of wear or potential issues before they escalate into major problems. For example, by regularly replacing filters, airflow remains unobstructed, preventing the furnace from overworking and reducing unnecessary strain on its components. This simple step can significantly enhance the performance and durability of the system.

Inspection, on the other hand, goes deeper into assessing the health of the furnace. It includes examining burners, heat exchangers, blower wheels, and other critical parts for signs of corrosion or damage. Through thorough inspections, technicians ensure that all safety protocols are met; this includes checking for gas leaks or carbon monoxide emissions which could pose serious risks to occupants of a household.

Effective repair techniques often stem from well-informed diagnoses made possible through regular maintenance and inspection. Skilled technicians use their understanding gleaned from constant monitoring to apply precise repairs that address root causes rather than just symptoms. For instance, calibrating a thermostat accurately requires an understanding of how it interacts with other furnace components – knowledge gained through regular checks.

Moreover, some advanced repair methods involve predictive maintenance strategies where data collected over time helps anticipate failures before they occur. Sensors can monitor various aspects like temperature fluctuations or unusual vibrations indicating an impending issue which allows preemptive repairs—a testament to how ongoing maintenance can make complex repairs more straightforward and effective.

In conclusion, regular maintenance and inspection form an integral part behind why certain gas furnace repair techniques are successful. These practices enable technicians to provide targeted solutions that improve efficiency while also prioritizing safety within homes. By staying proactive with upkeep schedules we not only save costs associated with emergency breakdowns but also enjoy peace-of-mind knowing our home's heating system is in good hands.

Advantages of Professional Diagnosis and Repair

When it comes to maintaining the warmth and comfort of our homes during the cold months, gas furnaces play an indispensable role. However, like all mechanical systems, they are prone to wear and tear that may necessitate repairs. While some homeowners might be tempted to attempt these repairs themselves, there are significant advantages to opting for professional diagnosis and repair.

Firstly, safety is a paramount concern when dealing with gas appliances. Gas furnaces involve combustible fuel, high voltage electricity, and moving parts—all of which can pose serious hazards if not handled correctly. Professionals have the training to identify risks and take appropriate precautions to prevent accidents such as gas leaks or electrical fires. They understand the importance of proper ventilation and are familiar with local codes and regulations designed to ensure safe operation.

Another advantage of professional service is the accuracy of diagnosis. Trained technicians possess in-depth knowledge about a wide range of furnace models and their common issues. They use sophisticated diagnostic tools that enable them to pinpoint problems quickly and accurately. This precision saves time and money by ensuring that only necessary repairs are performed, avoiding the trial-and-error approach that might occur with less experienced hands.

Moreover, an effective repair extends beyond merely fixing immediate symptoms; it involves understanding how different components interact within your heating system. Professionals can assess whether a malfunctioning part has caused additional strain on other components—something that might not be apparent at first glance but could lead to future breakdowns if left unaddressed.

Quality workmanship is another key benefit provided by professionals. Experienced technicians have honed their skills over numerous repair jobs, allowing them to perform repairs efficiently and effectively. Their work often comes with warranties that provide homeowners peace of mind—a guarantee that you're unlikely to get from DIY attempts or unqualified handymen.

Additionally, ongoing maintenance is crucial for keeping a furnace running effectively over its lifespan. Professional technicians can offer valuable advice on regular maintenance practices based on your specific model's requirements. By following their guidance, you can help prevent minor issues from escalating into major problems down the line.

Lastly, time is a critical commodity for most people today; attempting DIY furnace repairs can be incredibly time-consuming especially without prior experience or knowledge about the system's intricacies. Engaging professionals allows homeowners to focus on other important tasks or simply relax while experts handle the complex work swiftly.

In conclusion, while certain gas furnace repair techniques might seem straightforward at first glance, the effectiveness of those techniques often hinges upon expert application. flame sensor cleaning The advantages offered by professional diagnosis and repair—ranging from safety assurance to quality workmanship—are compelling reasons for homeowners seeking reliable solutions for their heating system troubles. By choosing seasoned professionals for this task ensures not just immediate fixes but also contributes towards long-term efficiency and safety of your home heating setup.

Common Gas Furnace Issues and Effective Solutions

Common Gas Furnace Issues and Effective Solutions

Gas furnaces are a reliable source of heat for many households, but like any mechanical system, they can experience issues that need attention. thermostat calibration Understanding why certain gas furnace repair techniques are effective is crucial to maintaining a warm and safe home during the colder months. Here we explore some common problems with gas furnaces and their corresponding solutions.

One prevalent issue with gas furnaces is a malfunctioning thermostat. The thermostat acts as the command center of the heating system, instructing the furnace when to turn on and off. When it's not working correctly, it could lead to a lack of heat or continuous running of the furnace. An effective solution is often as simple as replacing the batteries or recalibrating the thermostat. For more complex issues, rewiring or replacing the thermostat may be necessary.

Dirty filters are another common culprit affecting furnace performance. Over time, dust and debris clog the air filter, hindering airflow and forcing the furnace to work harder than necessary, which can shorten its lifespan. Regularly changing or cleaning filters is an easy yet effective solution that ensures efficient operation and prevents potential overheating problems.

Ignition or pilot control issues can leave you in the cold due to failures in lighting the burner. This might happen because of faulty electrical components or a dirty pilot light that needs cleaning. Technicians often tackle this problem by carefully cleaning ignition components or replacing them if they're beyond repair.

Wear and tear of mechanical parts such as belts and bearings can also lead to inefficiencies in your furnace's operation. These parts may become noisy or cause poor heating performance when they deteriorate over time. Repairing these issues effectively involves lubrication of moving parts where possible or replacing them entirely if they are damaged beyond use.

Heat exchanger cracks pose serious risks such as carbon monoxide leaks into your home; therefore, detecting this issue early is vital for safety reasons. Professional inspection can identify these cracks, leading to either welding repairs (if small) or replacement of the heat exchanger if required.

Lastly, inadequate maintenance can lead to various problems down the line from minor inefficiencies to major breakdowns requiring expensive repairs. Regular professional inspections ensure your furnace runs smoothly by identifying potential concerns before they escalate into bigger problems.

In conclusion, understanding why specific repair techniques work helps homeowners address gas furnace issues promptly and effectively. Simple fixes like changing filters regularly prevent larger complications while recognizing when professional help is needed for more complex situations guarantees safety and longevity for your heating system.

The Role of Advanced Diagnostic Tools in Repairs

The Role of Advanced Diagnostic Tools in Repairs

In the realm of gas furnace repair, the effectiveness of a technician's approach can be greatly enhanced by the use of advanced diagnostic tools. These sophisticated devices and software solutions enable a deeper understanding of complex heating systems, which in turn leads to more accurate troubleshooting, quicker repairs, and ultimately higher satisfaction for homeowners.

Advanced diagnostic tools come in various forms, including digital multimeters, combustion analyzers, infrared cameras, and HVAC-specific software that interfaces directly with modern furnaces equipped with electronic control systems. HVAC maintenance Each tool plays a pivotal role in deciphering the root causes of common issues such as uneven heating, strange noises, or complete system failures.

A digital multimeter allows technicians to measure electrical values with precision. This is crucial when diagnosing problems related to ignition systems or blower motors where exact voltage readings can indicate whether components are operating within their designed parameters.

Combustion analyzers go a step further by assessing the chemical composition of the exhaust gases produced by the furnace. By measuring levels of oxygen, carbon monoxide, and other gases, these tools provide insight into combustion efficiency and safety. This data can reveal issues like improper fuel mixtures or heat exchanger leaks—problems that could lead not only to decreased efficiency but also to dangerous conditions within the home.

Infrared cameras offer a visually intuitive way to identify heat loss and insulation deficiencies without invasive probing. By displaying temperature variations in vivid colors on a screen, they help pinpoint areas where heat escapes from ductwork or where there may be inadequate insulation around the furnace itself.

Lastly, many modern gas furnaces are equipped with self-diagnostic capabilities that generate error codes accessible through an interface module. When paired with proprietary software provided by manufacturers or third-party applications designed for HVAC diagnostics, these tools give technicians access to historical operation data and real-time performance metrics which significantly streamline the diagnostic process.

With these advanced diagnostic tools at their disposal, technicians can make informed decisions about what repair techniques will be most effective. For example:

- Accurate electrical measurements ensure that components like igniters are replaced only when necessary.

- Combustion analysis helps optimize burner performance for better fuel economy.

- Thermal imaging directs efforts towards sealing leaks rather than unnecessary component replacements.

- Software-guided diagnostics facilitate targeted repairs based on manufacturer-specific guidelines and error logs.

The utilization of technology in gas furnace repair not only aids in precise issue identification but also minimizes guesswork and reduces repeat visits—a win-win for both service providers and customers alike. It ensures that each intervention is tailored specifically to address the unique needs presented by individual systems while adhering strictly to safety standards.

In conclusion, advanced diagnostic tools have revolutionized gas furnace repairs by providing clarity and accuracy where traditional methods might fall short. They have become indispensable assets for HVAC professionals striving for excellence in service delivery while ensuring energy-efficient operation and prolonging equipment lifespan—all reflective of why certain gas furnace repair techniques are deemed highly effective today.

Replacement vs. Repair: Making Cost-Effective Decisions

Replacement vs. Repair: Making Cost-Effective Decisions in the Context of Gas Furnace Repair Techniques

When it comes to maintaining a comfortable and warm home during the cold season, ensuring that your gas furnace is operating efficiently is paramount. Homeowners often face the dilemma of choosing between repairing their existing furnace or replacing it with a new one. airflow testing The decision hinges on a variety of factors including cost-effectiveness, the age of the unit, technological advancements, and environmental considerations.

Why are certain gas furnace repair techniques effective? To begin with, some problems with gas furnaces can be relatively minor and easy to fix. These may include issues like replacing air filters, ignitors, or thermostats – tasks that do not require significant investment but can restore functionality and improve efficiency dramatically. An experienced technician can quickly diagnose such problems and perform repairs that extend the life of the unit without incurring the higher costs associated with replacement.

Another aspect to consider is regular maintenance which can prevent more severe issues from developing. Techniques such as cleaning burners, checking for proper ventilation, inspecting heat exchangers for cracks, and ensuring that all electrical connections are secure can keep a furnace running smoothly. By investing in these preventive measures regularly, homeowners can avoid costly breakdowns that might otherwise necessitate complete system replacement.

Moreover, some components within a gas furnace have longer lifespans than others; replacing these parts when they wear out or malfunction can be both cost-effective and environmentally friendly compared to disposing of an entire system. For instance, blower motors or control boards may fail after several years of service but swapping them out could make an aging furnace operate like new again.

However, there are times when repair might not be the most prudent choice. If a gas furnace has reached or exceeded its expected lifespan – typically around 15-20 years – it might be wise to consider replacement over repair. Older units often run less efficiently than newer models due to outdated technology and accumulated wear-and-tear; continually repairing them could become more expensive in the long run than investing in a modern energy-efficient model.

Furthermore, if a repair approaches or exceeds 50% of the cost of a new unit (a common rule-of-thumb), then replacement becomes a more sensible option economically speaking. Not only does this provide homeowners with peace of mind regarding reliability during critical heating months but potentially offers savings through reduced energy bills thanks to advances in technology.

In conclusion, determining whether to repair or replace your gas furnace depends on analyzing effectiveness versus expense while keeping future performance and sustainability in mind. Effective repair techniques focus on resolving specific manageable issues thereby extending service life at minimal cost while considering factors such as age and overall condition guide decisions toward replacement when necessary for greater long-term benefits both financially and ecologically.

Safety Considerations in Gas Furnace Repairs

Safety Considerations in Gas Furnace Repairs

When it comes to repairing gas furnaces, the effectiveness of certain techniques is closely linked to the safety measures implemented during the process. A gas furnace, by its very nature, involves combustible materials and potentially hazardous conditions; therefore, understanding and adhering to safety protocols is not just a best practice but an absolute necessity.

Firstly, one of the most critical safety considerations is ensuring that the repair technician is qualified and experienced. Gas appliances require specialized knowledge for safe handling. Certified professionals know how to detect risks such as gas leaks or faulty wiring, which could lead to dangerous situations like explosions or fires if not addressed correctly. These experts are trained in effective repair techniques that prioritize both functionality and safety.

Before any repairs begin, it's essential to disconnect the power supply and turn off the gas flow to prevent accidental ignition or electrocution.

Why Are Certain Gas Furnace Repair Techniques Effective? - furnace belt replacement

- flame sensor cleaning

- HVAC maintenance

Effective diagnostic procedures form another cornerstone of safe gas furnace repairs. By using sophisticated tools such as combustion analyzers or leak detectors, technicians can accurately identify problems without resorting to invasive methods that might compromise system integrity. For instance, detecting a crack in the heat exchanger—a component that separates combustion gases from breathable air—is vital because it prevents carbon monoxide poisoning.

Proper ventilation is another key factor. Even when a furnace appears to be functioning correctly after repairs, incomplete combustion can lead to carbon monoxide buildup within a home if there isn't adequate ventilation. Therefore, checking and maintaining vents and flues are part of effective repair strategies that ensure harmful gases are safely directed outside.

In addition, employing high-quality replacement parts during repairs enhances both efficacy and security. Using inferior components might solve an issue temporarily but could lead to future failures with more severe consequences. Authentic parts designed for specific models uphold manufacturer standards for performance and reliability.

Lastly, after completing any repair work on a gas furnace, thorough testing must be conducted before declaring the job complete. This includes checking for leaks again once everything is reassembled and verifying that all controls are working correctly through multiple operation cycles.

To sum up, effective gas furnace repair techniques integrate comprehensive safety measures at every stage—from preparation through diagnosis, actual repair work, final testing—and even into ongoing maintenance practices. Such an approach ensures not only the efficiency of heating systems but also protects against potential hazards associated with improper handling of these complex appliances—ultimately safeguarding homes and their inhabitants against avoidable accidents related to gas furnace operations.